White papers

Human milk is the ideal source of nutrients and vitamins for infants and is the most fundamental form of human nourishment. Many health agencies across the globe suggest exclusively breast-feeding for the first six months of life1. Under some circumstances, a mother’s milk production can be considered to be inadequate for her infant due to lactation and other difficulties. These situations necessitate an overarching system in which infants can be fed by mothers who are not their own. In these situations, expressed breast milk from a healthy wet-nurse or a human-milk bank can be provided.

Expressed breast milk is shared locally and internationally through milk banks and also via social media and the internet. However, the safe supply of these products to end users has not been successful thus far. A recent study showed that 89% of the milk arrived at customer’s location above the recommended temperature of -20 °C (-4 °F)2. Even if the recommended temperature is maintained, continuous cycles of refrigeration and thawing will deteriorate the milk’s integrity3,4.

The recommended temperature for frozen milk during transit is -20 °C (-4 °F)

In order to protect the quality of milk through risk points of the supply chain, passive insulation systems should be utilized to maintain the temperature at -20 ºC (-4 ºF) or below. These insulation systems function by reducing the heat transfer between the payload area and outside of the package by using materials with low thermal diffusivity and thermoregulators such as ice, gel packs, and dry ice. Insulated Products Corporation (IPC) offers an environmentally preferred and fully recyclable insulating solution for human milk shipment that thermally and economically outperforms rigid coolers.

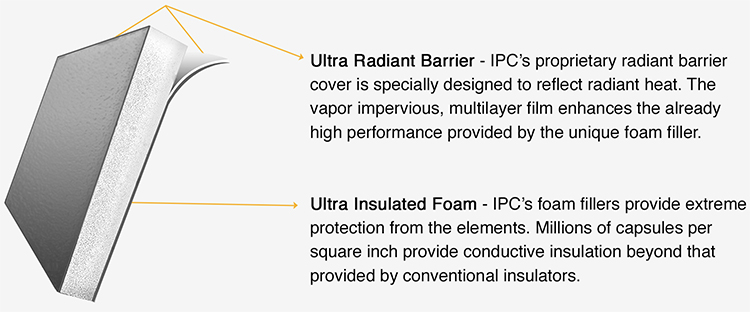

The State-of-the-Art Technology

PopupLiner insulated box liners are IPC’s high-performance and innovative insulated shipping boxes. Each PopupLiner unit is composed of two three-panel, tri-fold liners for a six-sided box. The insulated shipping boxes are unique in that they provide an alternative form of temperature-control packaging that is both fully collapsible and compressible using IPC’s patented technology.

The self-inflating and expanding thermal liners arrive compact and vacuum-compressed in compression sleeves and will inflate automatically to full thickness upon opening. These liners are effective to protect refrigerated, frozen, and room-temperature (RT) products for 48+ hours (making them perfect for 48 hour frozen shipping for products such as vaccines). The PopupLiner insulated boxes are shipped compressed and will inflate to full pre-compressed thickness upon opening of the compressed vacuum sleeve. The space-efficiency feature will save 75% in shipping and storage space as compared to the equivalent in rigid coolers.

Risk Mitigation Study of Human Milk Distribution by PopupLiner Insulated Box Liner

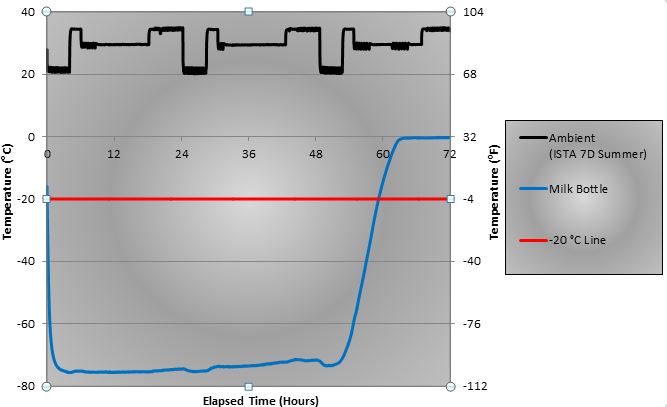

An experiment was devised to obtain the maximum transit time that the milk containers can be kept below -20 ºC (-4 ºF) using PopupLiner insulated box liners during transport. PopupLiner insulated containers with a thickness of 2″ were used to insulate 10 bottles of human milk. A T-type thermocouple was placed inside the milk bottle to measure the temperature during the operational qualification procedure.

The figure below shows the milk bottle temperature inside the cartons (°C) versus elapsed time (hours) inside the PopupLiner insulated box liner. The test was conducted under extreme summer conditions of ISTA 7D summer. The milk temperature fluctuates according to the unsteady thermal status of the oven. The experimental results presented herein indicate that the 2″ thick PopupLiner thermal box liner maintained the temperature below -20 °C (-4 °F) for 60 hours with dry ice.

Summary

Expressed human milk is helping sick and premature infants thrive. The commercialization of the expressed breast milk requires a flawless cold chain to protect the safety of the consumer by maintaining the milk temperature at a temperature of -20 °C (-4 °F) or below. A test was designed to assess the passive thermal protection of IPC’s PopupLiner insulated box liner for expressed milk shipment. According to the test results presented herein, IPC’s PopupLiner insulated container maintained the milk temperature below -20 °C (-4 °F) for 60 hours when used with enough dry ice.

About Insulated Products Corporation (IPC)

Founded in 1999, IPC has been an innovator of thermal packaging solutions. We have spent over a decade studying, perfecting, consistently producing and delivering effective cold chain thermal packaging to companies shipping medicines, foods, and industrial goods worldwide. IPC designs and manufactures, in-house, a variety of custom temperature control products for the cold chain shipping industry. All of IPC’s solutions provide high performance, while remaining space-efficient and green. We thrive on special requirements including custom sizes, extended shipping durations, unique temperature requirements, and sustainability. Maintaining strict temperatures, maximizing payload, minimizing weight and preparation time are the cornerstones of IPC cold chain solutions.

Contact us today to discuss your unique temperature assurance packaging requirements.

References

1- WHO/UNICEF. Global Strategy for Infant and Young Child Feeding, Geneva, Switzerland, World Health Organization, 2003.

2- Sheela R. Geraghty et al., “Buying human milk via the internet: Just a click away”, Breastfeeding Medicine, 2013, Vol. 8, pp. 474-478.

3- A. Pardou et al., “Human milk banking: influence of storage processes and of bacterial contamination on some milk constituents”, Biology of the Neonate, 1994, Vol. 65, pp. 302–309.

4- I. H. Buss et al., “Vitamin C is reduced in human milk after storage”, Acta Paediatrica, 2001, Vol. 90, pp. 813–815.