White papers

The frozen food industry aims at providing customers with safe, high-quality food products. Proper transport and storage of frozen foods throughout the distribution process is essential to maintaining food safety and quality. The packages containing frozen foods should be constructed, thermally insulated and equipped with sufficient refrigerants to continuously maintain product temperature of 0°C (32°F) or colder. Insulated shipping boxes are needed as they limit the exchange of heat between the environment and the inside of the package, thus delaying the time in which the temperature inside the package reaches equilibrium with the ambient temperature.

IPC’s PopupLiner Insulated Box Liner

Pint of Ice Cream

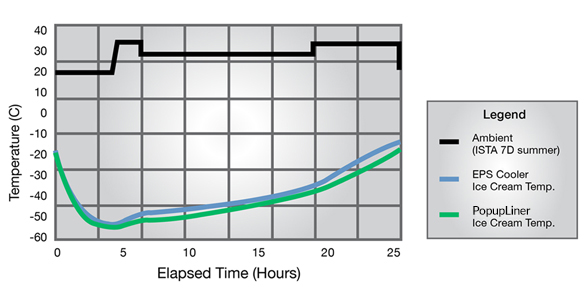

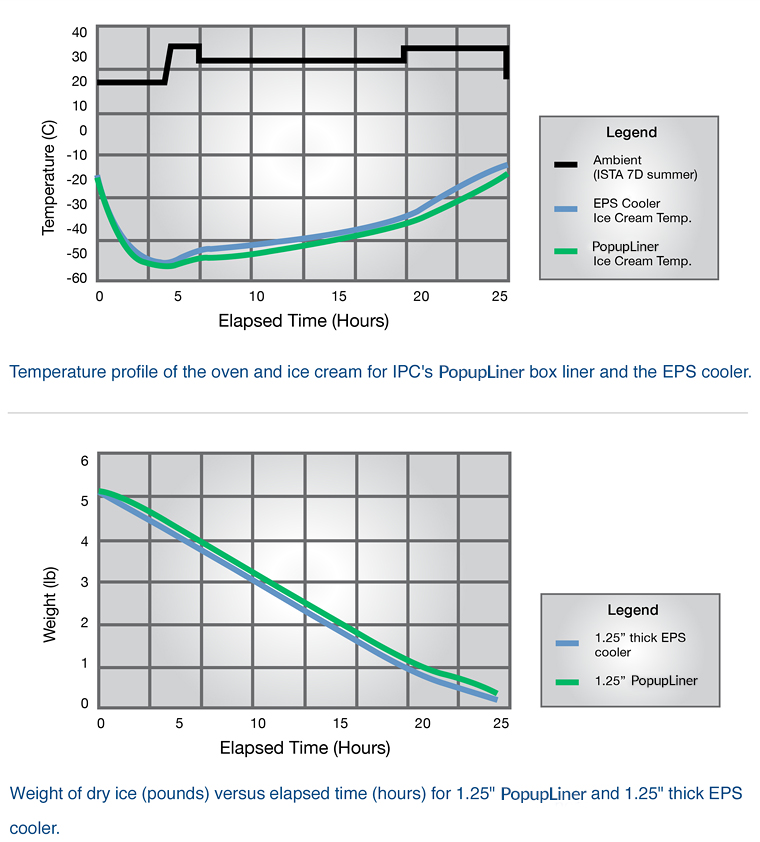

Temperature profile of the oven and ice cream for IPC’s PopupLiner Insulated Box Liner and the EPS cooler.

One of the most commonly used thermal insulators in the food industry is expanded polystyrene (EPS) coolers. IPC, however, offers a far superior product.

There are some advantages in using EPS shipping coolers: they are thermally insulating, relatively lightweight, and cheap. However, due to its environmental impact and non-biodegradability, over 100 counties in the United States, including the counties of Los Angeles, CA; Portland, OR; New York, NY; Washington, DC, have already outlawed polystyrene foam. While some polystyrene foam is reused, the majority used for food or beverage containers are one-time use materials.

Recycling EPS is technically possible, but it is a very costly process. Also cited as a potential drawback is the uncertainty about the long-term health effects of chronic exposure to EPS Styrofoam products, particularly those used in the food industry. In addition, although lightweight, EPS coolers are extremely bulky and must be shipped stacked. This renders the shipping and warehouse storage inefficient and unreasonably costly.

Given the aforementioned disadvantages, IPC offers various insulated shipping solutions to replace current EPS coolers while improving thermal performance and reducing transportation cost for frozen food transport.

The Technology

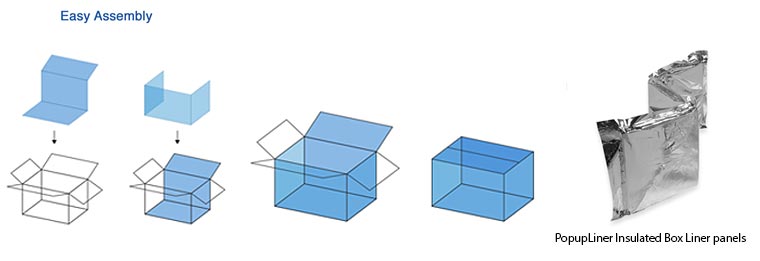

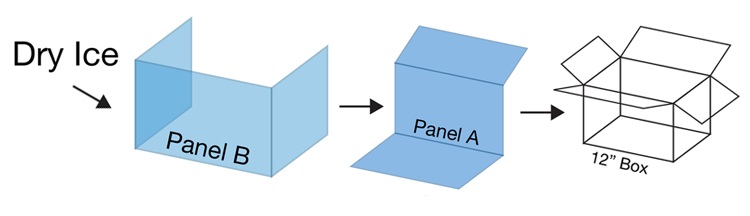

PopupLiner thermal box liners are IPC’s solution to a high performance thermal container. Each PopupLiner box liner is composed of two three-panel tri-fold liners for a six-sided box. The insulated boxes are unique in that they provide an alternative form of temperature-control packaging that is fully collapsible and compressible using IPC’s patented technology. (Patent #US 8,333,279)

Thermal Performance Comparison of IPC’s PopupLiner Box Liner

EPS coolers, and IPC’s insulated box liners (with wall thickness of 1.25″) were tested under controlled conditions in an industrial oven to compare the thermal performance in maintaining the frozen state of a pint of ice cream.

The experiments were designed to assess the sublimation rate of dry ice and record the ice cream temperature in IPC products and EPS coolers.

We placed the same amount of dry ice (5lb) in each pack-out, exposed the shippers to a standard summer temperature profile (ISTA 7D 24h summer), and measured the remaining dry ice intermittently throughout the experiment. The weight of the dry ice versus elapsed time is plotted below.

It is established that IPC’s PopupLiner insulated shipping box thermally outperforms EPS coolers and reduces dry ice consumption, depending on application, by up to 33%.

Thermal Performance Comparison of IPC’s PopupLiner Box Liner

Space-Efficiency: A Deciding Factor in Cold Chain

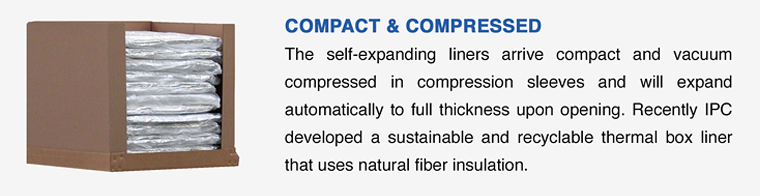

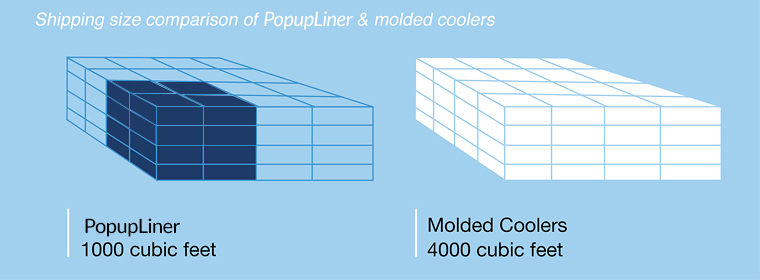

Unlike EPS coolers that are bulky and are shipped in their final form, IPC insulated boxes arrive collapsed and fully compressed. Using compressed IPC products will save 75% in shipping and warehouse space as compared to same numbers of EPS coolers.

This staggering space-efficiency feature helps IPC’s clients receive industry-best pricing made possible by the reduced inbound freight cost as well as savings in labor achieved via the reduced handling requirements.

This makes IPC’s insulated shipping products one of the most cost-efficient substitutes for EPS cooler containers on the market today. In addition, IPC’s PopupLiner panels absorbs shock and stress from rough handling.

Summary

The comparative study demonstrated the superiority of the temperature-controlled insulated box liners designed and manufactured by IPC as compared to EPS coolers in maintaining low temperatures used in transport of frozen food. Although EPS coolers are one of the most widely used insulating products in the food industry; some of its disadvantages, such as mediocre thermal performance, high storage volume, and non- biodegradability, make its use economically unjustifiable.

IPC can provide alternative insulating solutions to EPS coolers with no tooling cost while providing 75% savings in shipping space and significant reduction (up to 33%) in required dry ice required for frozen food transport.

These solutions offer affordable thermal protection without the downsides of high shipping expense and large storage requirements normally associated with insulting products such as EPS coolers.

About Insulated Products Corporation (IPC)

Since being founded in 1999, IPC has been an innovator of thermal packaging solutions. We have spent over a decade studying, perfecting, consistently producing and delivering effective cold chain thermal packaging to companies shipping medicines, foods, and industrial goods worldwide. IPC designs and manufactures, in-house, a variety of custom temperature control products for the cold chain shipping industry.

All of IPC’s solutions provide high performance, while remaining space-efficient and green. We thrive on special requirements including custom sizes, extended shipping durations, unique temperature requirements, and sustainability. Maintaining strict temperatures, maximizing payload, and minimizing weight and preparation time are the cornerstones of IPC cold chain solutions.

Contact us today to discuss your unique temperature assurance packaging requirements