A national supermarket chain services its locations using numerous distribution centers located nationwide. The retailer has a large private fleet of reefer trucks, set at 36° F, that service all locations.

The Challenge

Only a small proportion of products (dairy and deli) shipped to the supermarkets can be transported at 36 °F. Other products, including frozen meats, need to be transported at lower temperatures using the same reefer containers in order to achieve more efficient shipping. To avoid defrost and damage to the pallets of meats and produce respectively, the company must use equipment that produces specific temperatures at various “zones” inside their trailers.

This equipment produces many challenges: tedious loading into various zones and unloading goods at different temperatures at various retail locations. The equipment also reduces fuel efficiency, not to mention the added cost of the equipment itself.

Proposal

The retailer approached IPC with the desire to protect its pallets of produce and meats in order to ship those products, along with dairy and deli products, inside trailers set at 36 °F. They also requested that the solution be low-cost, easy to use and environmentally friendly.

IPC Recommendation: CooLiner Pallet Covers

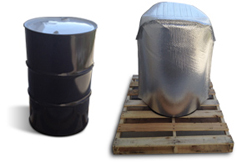

IPC recommended its high–performance CooLiner Pallet Cover to deal with the varying optimal temperatures inside the reefer (36 °F).

CooLiner Insulated Pallet Blankets, which use a proprietary combination of insulating foil and thermoplastics, have proved to produce significant temperature differentials when covering temperature–sensitive cargo.

The pallet covers’ proprietary technology gives them the unique performance capabilities that make them appropriate for insulating applications such as this.

Testing

After preliminary data indicated positive results, IPC recommended that the retailer conducted an internal study using the CooLiner Pallet Covers to test their effectiveness. The retailer subsequently conducted a detailed trial with several test shipments, some with blanket insulation and some without.

Conclusion & Results

The retailer determined that IPC’s CooLiner Pallet Covers provided an adequate temperature differential between the van’s interior and the cargo inside the pallet covers.

This ensured that produce and meats would arrive in saleable condition when stored in a reefer set at a less– than–optimal 36 °F.

When utilizing the insulation blanket, the retailer was able to ship all goods, including dairy, deli, meat and produce, inside the same trailer, set at one consistent temperature. The company experienced the following benefits:

- More convenience when loading goods inside trailer: No need to stagger pallets in optimal ‘zones’.

- Improved fuel efficiency: No need for special equipment to produce temperature ‘zones’.

- Reduced cost: No need to purchase and install special equipment inside trailers.