Frozen products such as beef, poultry, and blood plasma are highly susceptible to changes in ambient temperature, making it difficult to control against external temperature fluctuations. Shipping frozen foods usually requires the use of dry ice. To make things simple, Insulated Products Corporation (IPC) has provided a step-by-step guide on the best practices for shipping frozen products.

PopupLiner Box Liner is the perfect solution for shipping meat and other frozen food products.

How to Ship Frozen Products: Step-by-Step Guide

Firstly, it is important to understand that dry ice shipments stay frozen as long as there is solid dry ice remaining in the package. The length of time that dry ice will last depends on the ambient temperature, insulation thickness, and other variables. After this timeframe, the packed product begins to defrost, and eventually spoils as rising temperatures lead to the increased growth rate of microorganisms. Utilizing the appropriate amount of dry ice with the correct caliber of insulation is key to a successful shipment. A general rule of thumb is to use approximately 5 lb for every 24-hour period your frozen product will be in transit.

The PopupLiner Box Liner is ideal for shipping ice cream

1. Place an insulated box liner inside your box

Firstly, your insulated container should be lined with an insulated box liner, used as the foundation for building out the rest of your package. (Note: We advise against shipping with molded containers for either bulk or individual shipping orders. Not only are they less effective than PopupLiner insulated box liners, they are also bulky and contribute to greater landfill volume if they are not recycled)

2.Place your frozen products and dry ice inside the container

Place your frozen products inside the pre-lined container, then add dry ice as needed. Place blocks of dry ice on top of your perishable goods. You can even add pellets of dry ice to fill in the air gaps. Be sure to allow enough head space for the PopupLiner lid to shut without making contact with the dry ice. You should avoid overfilling the package to the extent that the insulator gets squeezed between the container and the shipped goods.

3. Fill any empty spaces within your package to improve thermal efficiency

Minimize any empty air space where possible by using filling materials, such as foil insulation rolls. Extra air inside the package allows circulation of diffused heat, leading to suboptimal thermal performance.

4. Close your insulated container, allowing slight air flow for ventilation

Close the insulated box container, but do not seal it off completely. It is important to ensure that a small amount of the sublimated gas is able to vent through your insulated container. Venting is necessary to prevent a dangerous build-up of pressure.

Meat shipping requires effective thermal control during transit to protect it against odors, off-flavors, and spoilage.

Best Insulated Packaging for Shipping Frozen Food

Insulated Products Corp. provides the supplies you need to maximize efficiency while keeping products frozen during transport. We have been in the insulated shipping business since 1999 and strive to help businesses excel in their daily functions.

PopupLiner Box Liner

The PopupLiner Box Liner is our most high-performance product line, built to offer extremely powerful temperature control when shipping frozen goods. The liners are made using a unique, space-saving design that makes them incredibly cost-efficient to store and handle.

Cold Packs

Refrigerant cold packs are highly useful in conjunction with dry ice to prolong the time frozen shipments remain frozen while in transit. We offer various types of gel packs, including drain-friendly recyclable gel packs and sweat-proof gel packs.

Read our case study about how well our PopupLiner insulated boxes perform in combination with dry ice.

Request a quote to find our how you can use IPC insulated packaging products to protect your products while in transit

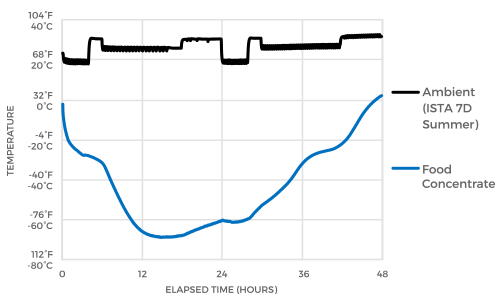

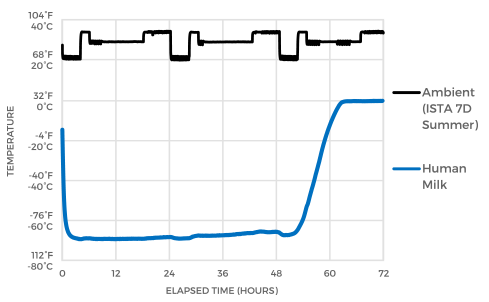

Performance Testing of IPC Box Insulation when Shipping Frozen Products

The below tests were performed to assess the performance of our insulated box liners in maintaining cold temperatures of frozen food products while in transit.

Thermal Performance of IPC’s EcoLiner Box Liner for Frozen Meal Shipment

Do you need a reliable solution for shipping frozen products?