A large pharmaceutical chain with locations worldwide must maintain controlled room temperature (20°C to 25°C) when transporting various medicines, including capsules, pills and process material. Shipping in very hot or cold climates results in extreme spikes and dips in temperature, which can be detrimental to the quality of the medicines. Some excursions were experienced at airports during wait periods. The regulatory bodies indicate that these goods must remain at temperatures between 20°C and 25°C during storage and transport.

The client had received warnings from regulatory bodies indicating that the pharmaceutical packaging being used was allowing cargo to experience temperature excursions during transport. It was necessary to take the required steps to ensure better protection of their goods against spikes and dips in temperature.

Proposal

The pharmaceutical chain approached IPC with the desire to procure a form of insulating cover that could be used to protect cargo during the summer and winter months. It was a priority that the client would be able to ship with the same mode and route they used previously. They also requested that the solution be low-cost, easy to use and environmentally friendly.

IPC Recommendation: CooLiner Pallet Cover

IPC recommended its high–performance CooLiner Pallet Cover to protect against the temperature spikes and dips that occur during transport using dry containers and air freight.

CooLiner Insulated Pallet Covers are pallet blankets that utilize a proprietary combination of reflective foil and thermoplastics to produce significant temperature differentials when covering temperature–sensitive cargo.

This film technology gives the pallet covers unique performance capabilities that make them appropriate for this type of application.

Testing

IPC was provided with a characterization study for CooLiner pallet covers from a third-party independent testing organization, which is available upon customers’ request.

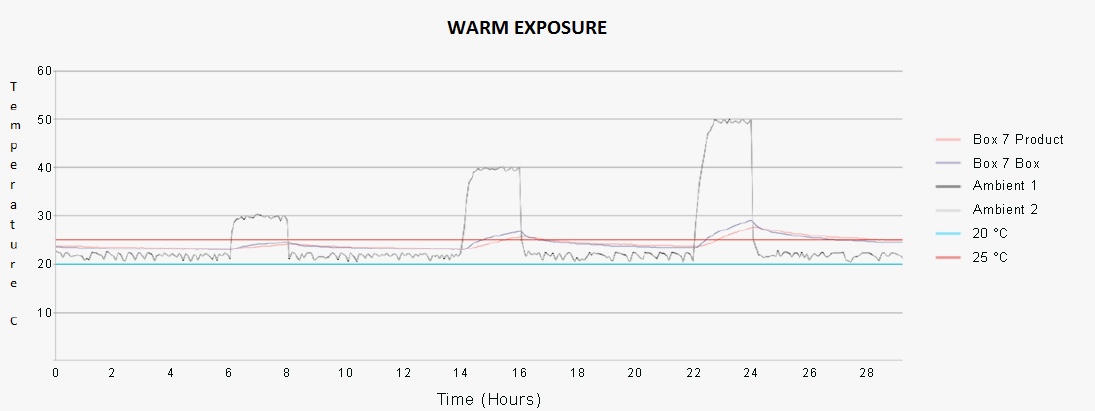

The study used hot and cold temperature profiles likely to occur in actual usage to assess the effectiveness of CooLiner pallet covers in maintaining controlled room temperature.

The payload was HDPE bottles filled with a solid, oral-dose tablet substitute – softener salt pellets. Thermocouples were used in accordance with the protocol and were placed at multiple locations inside the product. Another thermocouple was placed outside of each case containing a monitored HDPE bottle. Finally, two thermocouples monitored the ambient chamber temperature, ensuring adherence to the temperature profile specified in the protocol.

The temperature profiles used were designed to simulate the short-term temperature excursions that occur in temperature-controlled trailers as a result of door opening or docking activities. LTL shipments are often exposed to repetitive door openings. This is another set of conditions where pallet blankets can effectively reduce the short-term effects of exposures to both warm and cold conditions.

The USP Good Storage and Shipping Practices calls for an interval of no more than 2 hours for putting away drug products. Best practice in the DCs is to offload the product and place it immediately in the appropriate storage condition, ensuring that the last pallet off the truck would have had no more than a 45-minute exposure to uncontrolled conditions.

All thermal tests for cold exposure were well above 10 ºC, safely above the freezing point at which physical and phase changes may occur. Generally, the exposure of CRT products to low temperatures is not problematic as long as the product temperatures do not result in physical changes. For the hot exposure test, the thermal results showed that after a two-hour exposure to ambient temperatures as high as 50 °C, the CooLiner pallet cover was able to keep the product below 30 °C for one hour and below 40 °C for two hours. The results for the product temperature and oven temperatures versus elapsed time is shown below.

After preliminary data demonstrated positive results, IPC recommended that the company ran an internal study to assess the effectiveness of CooLiner Pallet Covers during transit. The pharmaceutical company subsequently conducted a trial with several test shipments using the insulated pallet covers.

Conclusion & Results

The retailer determined that the Insulated Pallet Covers provided a temperature differential of over 30°C between the van’s interior and inside the thermal covers. This resulted in protection that was more than adequate and ensured that confectionery goods would arrive in saleable condition.

By utilizing IPC’s pallet box covers, the retailer has now entirely eliminated use of reefer containers, resulting in:

- Large savings in shipping costs–no need to hire reefer trucks.

- Internal improvements in efficiency.