White papers

The United States is the largest wine market in the world1 . It is projected to be one of the fastest growing markets in both consumption and production due to government support, e-commerce readiness, increasing awareness about the medical benefits, and a growing younger generation.

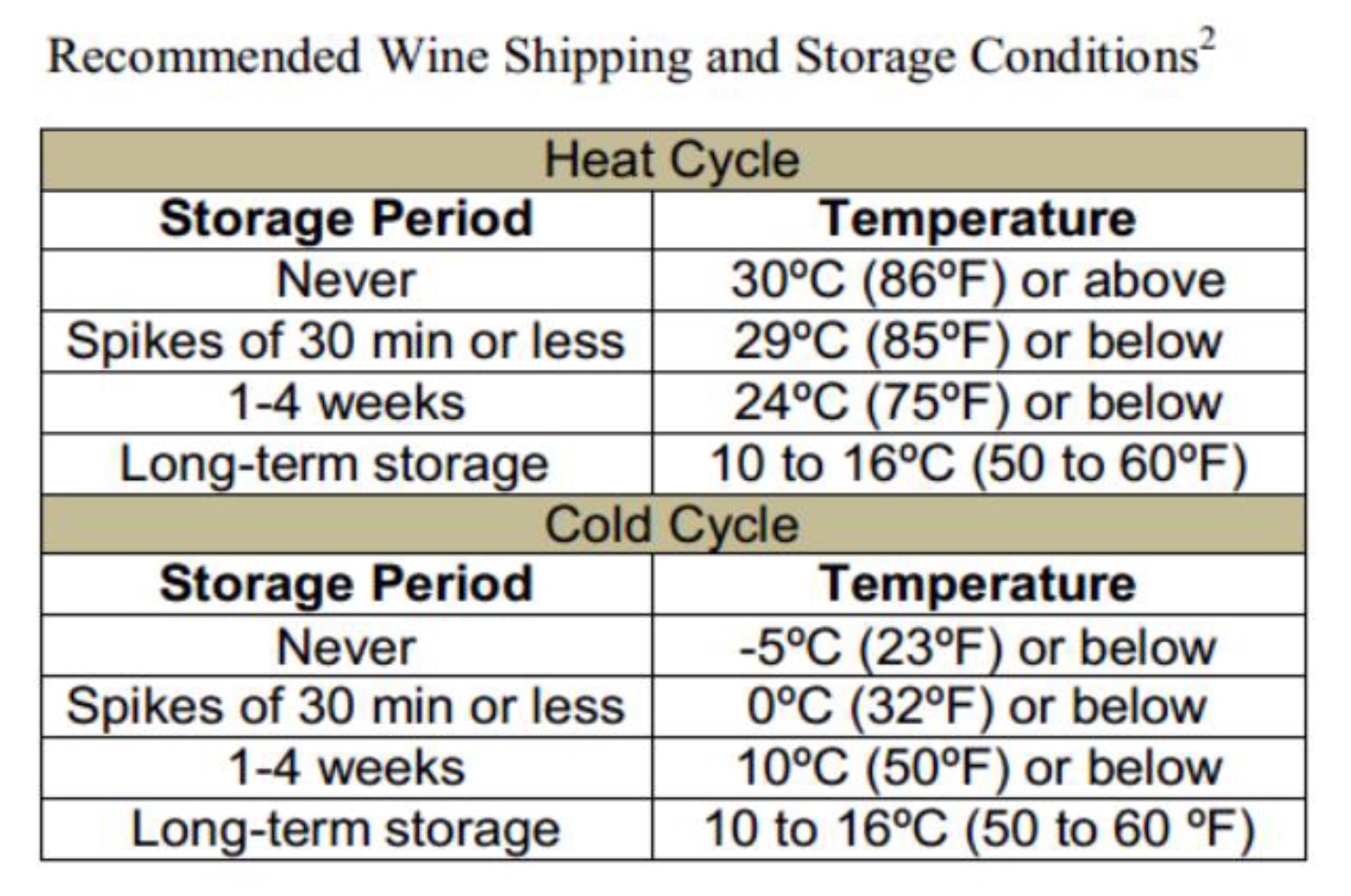

The storage and shipment of wine require special consideration as multiple factors — such as temperature, light, humidity, and vibrations — can potentially compromise the wine’s quality. Of all the factors, wine is very susceptible to fluctuations in temperature, and should be stored at cellar temperatures between 10 and 16°C (50 to 60°F)2. The hundreds of concurrent aging reactions that contribute to the aroma3, flavor, color4,5, and healthiness of a wine all proceed at individual rates that are accelerated by elevated temperatures2. Therefore, wine is considered to be a temperature-sensitive product that requires a temperature-controlled supply chain.

In order to keep the wine’s quality intact throughout the supply chain, savvy logistics managers tend to implement passive temperature-protection solutions as opposed to active controllers, such as reefer trailers, which are cost prohibitive. Passive insulation works by decreasing the rate of heat transfer using mediums with low thermal conductivity, such as expanded polystyrene foam (EPS) and polyurethane foam.

Individual wine shipments can be delivered in EPS coolers that protect them from excessive temperature fluctuations, but they are too brittle to be used consistently and not readily recyclable. These coolers possess suboptimal thermal insulating properties and are extremely bulky for shipping and storage purposes.

IPC offers an environmentally preferred and fully recyclable insulating solution for wine shipment that thermally and economically outperforms EPS coolers.

Thermal Storage Conditions of Wine

What’s too hot for wine?

Temperatures above 16°C (60°F) may cause the growth of dormant microbes, leading to off- flavors, browning, and premature aging. Storage at elevated temperatures may also cause excessive extraction of odors from the bottle closures, as well as increased scavenging and permeation-based loss of protective sulfur dioxide or wine aromas. According to the National Toxicology Program, most wines contain traces of a precursor to a probable human carcinogen6 , ethyl-carbamate, which can form at temperatures above 30°C (86°F).

What’s too cold for wine?

Wines stored at temperatures cooler than 10°C (50°F) may not develop their full potential for aroma, flavor, and color. Storage at extremely low temperatures — 0°C (32°F) and below — for as little as 1 hour can cause the natural precipitation of potassium bitartrate in the form of visible crystals in white wines and in the form of colored crystals in red wines. This material is not resoluble in the wine, and while its presence is considered only a visual defect, consumers may confuse it with broken glass. At temperatures below -5°C (23°F) wines will start to freeze, expand in size and eventually compromise the bottle.

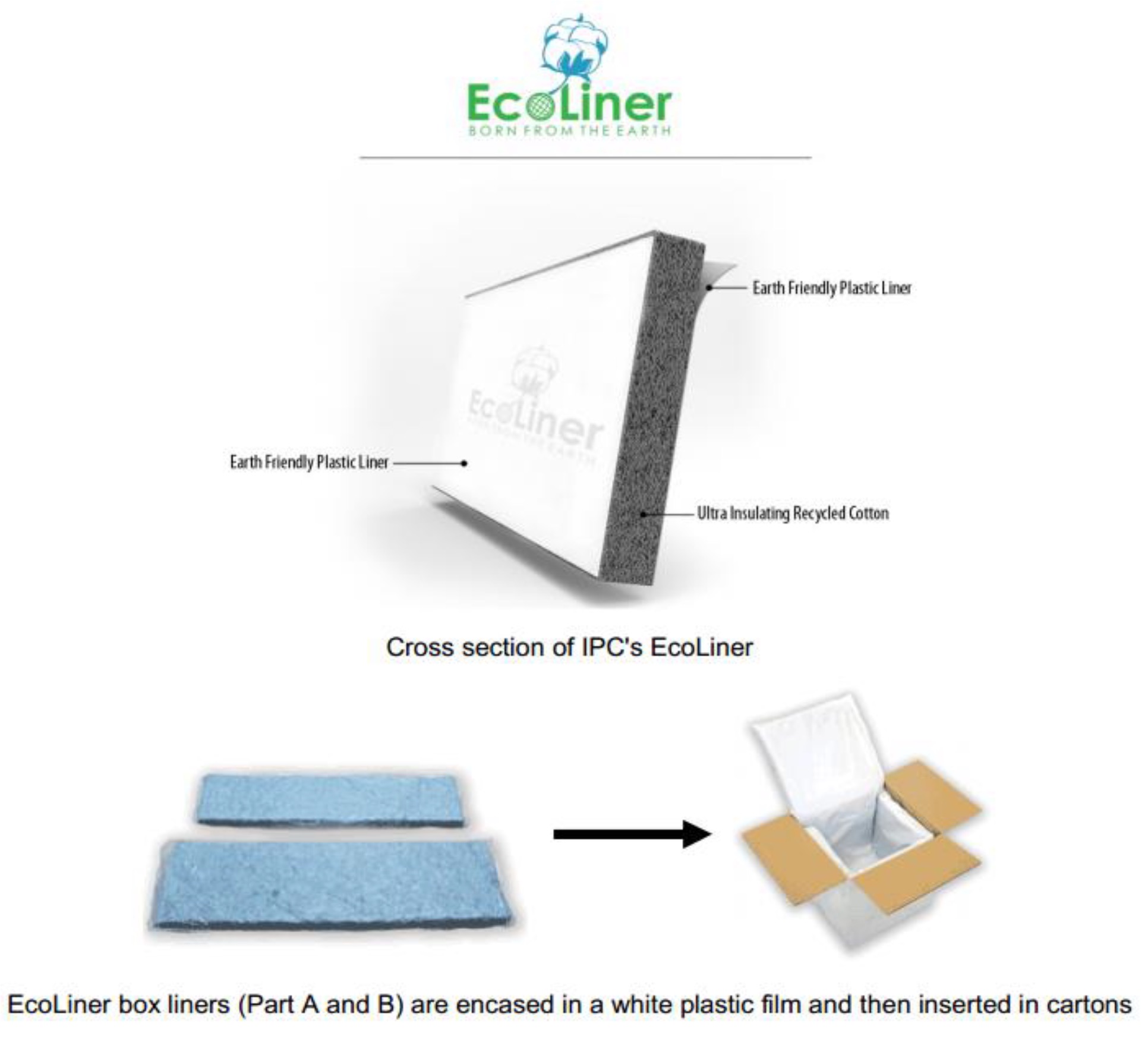

The Technology

IPC’s EcoLiner insulated box liner is a two-piece thermal insulation liner made to thermally and physically protect the contents of a six-sided container. The EcoLiner’s high performance stems from the natural cotton-based panels that are wrapped in a bio-based film. EcoLiner insulated box liners are encased in a white plastic film and are then inserted into corrugated boxes. These box liners effectively protect refrigerated, frozen, and room-temperature (RT) products for over 48 hours.

The insulated box liners are shipped compressed and will inflate upon opening of the compressed vacuum sleeve. This space efficiency feature will save 75% in shipping and storage space as compared to the equivalent in rigid coolers.

Experiment: Thermal Protection Performance of EcoLiner

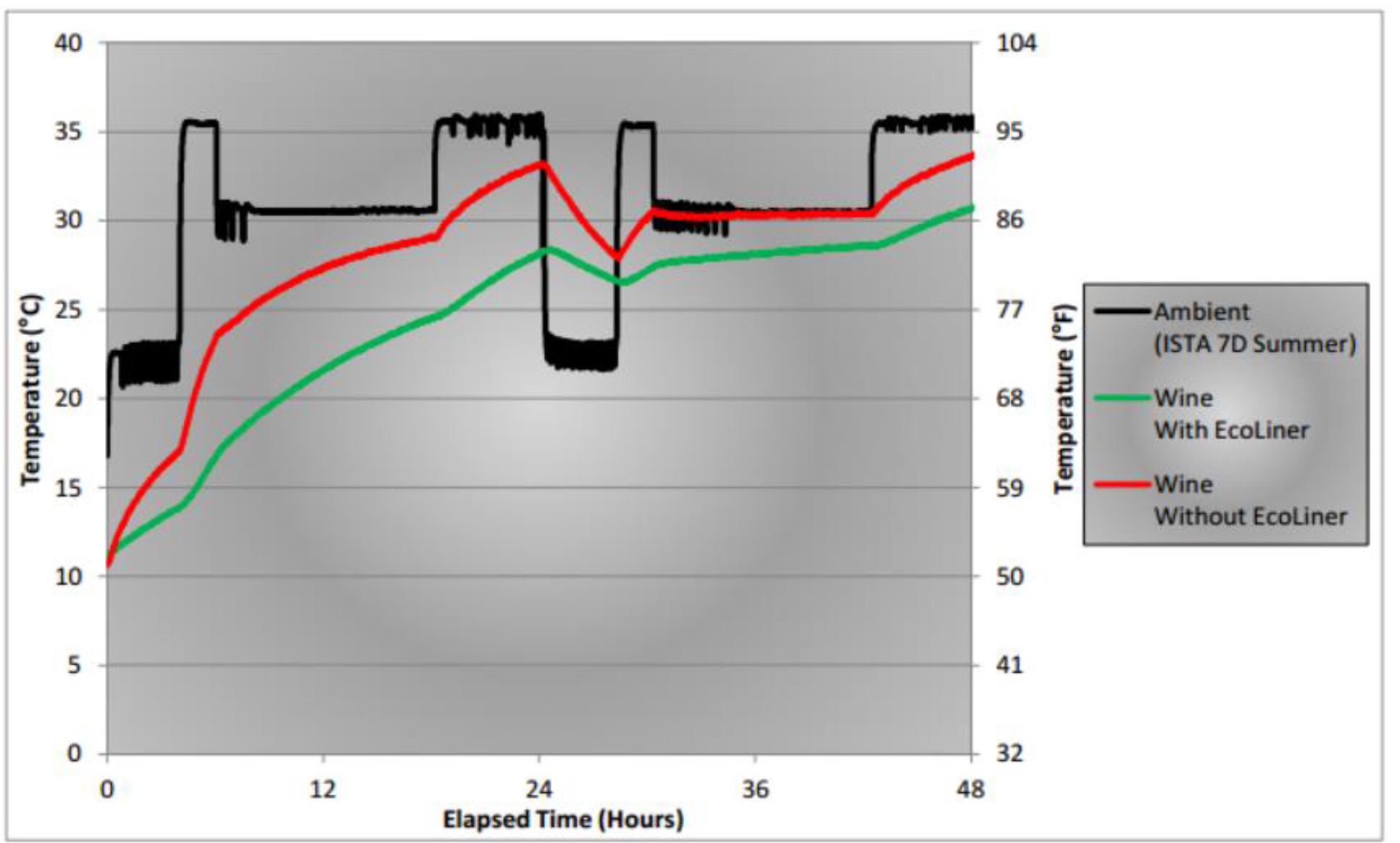

A comparative experiment was devised to evaluate the effect of EcoLiners on temperature fluctuations within an insulated shipping container during transport.

Four bottles of wine were placed inside molded pulp packs and inserted inside a corrugated carton. The wine bottles were tested with and without the EcoLiner thermal box liner. An EcoLiner insulated box liner with a thickness of 1″ was used to insulate and enclose one of the wine shippers. The wine bottles were preconditioned at 11°C, which is considered to be an ideal temperature for wine storage7. The positioning of the wine shipper inside the 1″ EcoLiner thermal box liner is depicted on the right.

After loading the wine shipper inside the EcoLiner thermal box liner, the box was taped shut. A T-type thermocouple was placed inside the wine bottle to measure the temperature during the operational qualification (OQ) test.

The figure below shows the wine temperature inside the cartons versus elapsed time for samples of wine shipped both with and without the EcoLiner insulating box liner. The test was conducted under extreme summer conditions. The wine temperature fluctuates according to the unsteady thermal status of the oven. The experimental results indicated that the EcoLiner insulated box liner postpones reaching the “forbidden” temperature of 30°C, as shown in the table below.

The temperature inside the wine shipper without EcoLiner box liner reached 30°C after 19 hours, whereas wine temperature insulated with an EcoLiner insulated box liner reached 30°C after 46 hours and 25 minutes.

Temperature profile of wine with and without the EcoLiner Box Liner

Package Integrity

In general, any insulated packaging must be of good quality, and strong enough to withstand shocks and stresses normally encountered during transport and handling. As wine bottles are made of glass, packaging needs to be robust enough to keep them from breaking. IPC’s insulated containers, in addition to the enhancement of insulating properties, act as a functional cushioning material that further protects wine shippers against accidental drops and impact.

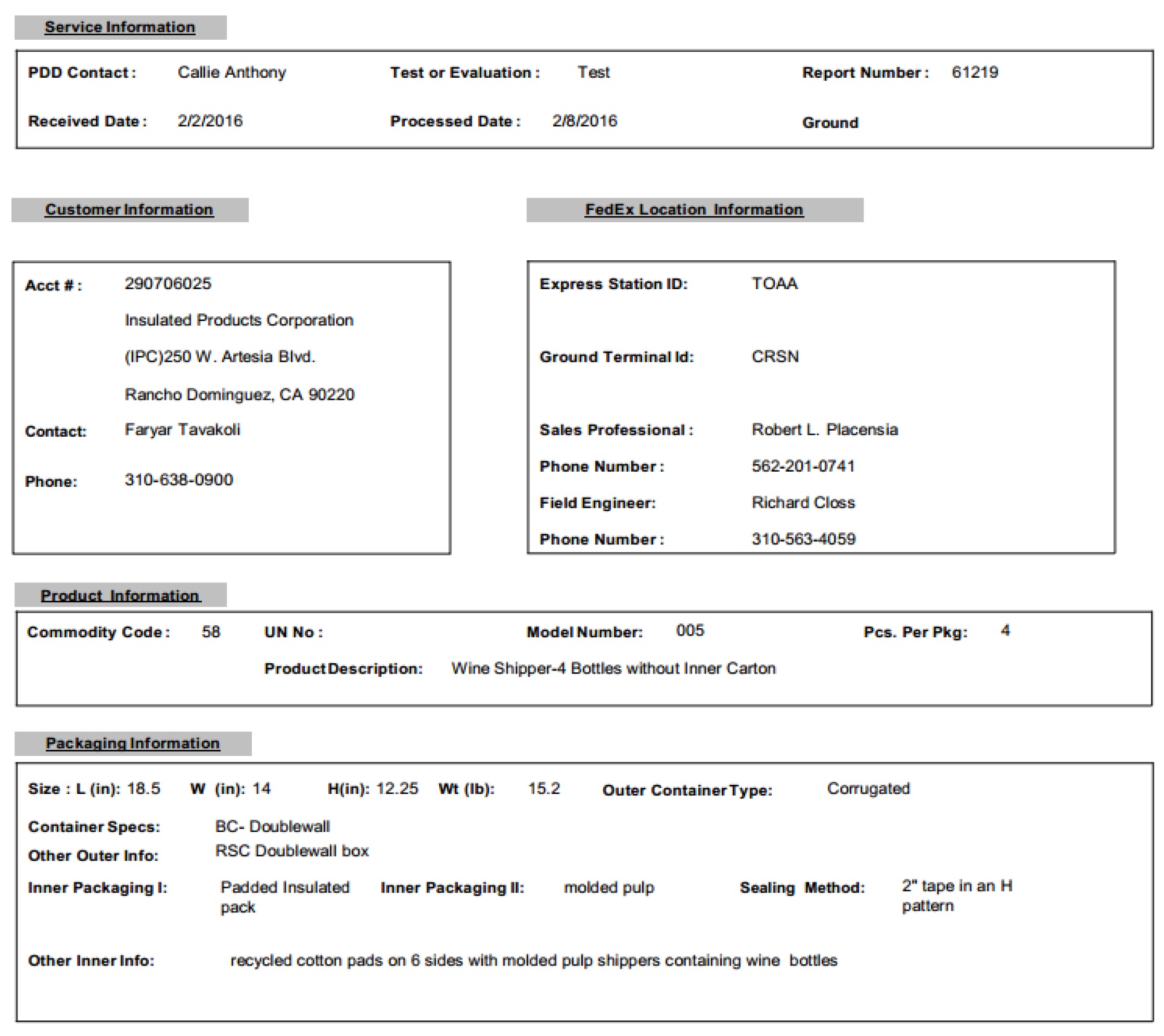

In order to evaluate the integrity and protective performance of the wine packaging, the samples tested for thermal performance were also tested by FedEx under ISTA-6-FedEx-A protocol. The protocol entails a strict sequence of testing procedure such as free-fall drop test, compression test, and vibration test. The proposed wine package met the minimum packaging requirement for safe transit via FedEx. The FedEx report is included below:

FedEx Package Test Report

Summary

Americans are consuming more wine than ever before. This growth in consumption increased the total shipment of wine, especially directly to consumers. Wine is considered to be a temperature-sensitive product that needs a thermally controlled and uninterrupted series of storage and distribution practices. A test was devised to assess the added protection of EcoLiner insulated box liners for wine shipment. The test was executed under extremely hot conditions. According to the test results presented herein, IPC’s insulated containers significantly postpone reaching a temperature of 30°C (86 °F), a level which is detrimental to wine.

It is worth reiterating that most wines contain traces of a precursor to a probable human carcinogen6, ethyl-carbamate, which can form at accelerated rates above 30°C (86°F)2. In addition, our EcoLiner thermal box liner provides a functional cushioning material that further protects the current wine shippers against accidental stress and impact. In order to evaluate the integrity and protective performance of the wine-insulating packaging, the samples tested for thermal performance were also tested by FedEx under ISTA-6-FedEx-A protocol. The proposed wine package met the minimum packaging requirement for safe transit via FedEx.

References

1- U.S. Department of Commerce, “U.S. Wine Industry – 2011” http://ita.doc.gov/td/ocg/wine2011.pdf

2- C. Butzke, “Wine Storage Guidelines”, 2010, extension.purdue.edu.

3- A. F. Recamales et al., “Effect of time and storage conditions on major volatile compounds of zalema white wine”, Journal of Food Quality, 2011, Vol. 34, pp. 100-110.

4- Z. Czibulya et al., “Unexpected effect of potassium ions on the copigmentation in red wines”, Food Research International, 2012, Vol. 45, pp. 272-276.

5- C. A. Sims and J. R. Morris, “Effects of PH, sulfur dioxide, storage time, and temperature of the color and stability of red muscadine grape wine”, American Journal of Enology and Viticulture, 1984, Vol. 35, pp. 35-39.

6- https://ntp.niehs.nih.gov/ntp/roc/content/profiles/urethane.pdf

7- T. Stevenson, “The Sotheby’s Wine Encyclopedia”, p. 46. Dorling Kindersley, 2005.

About

Since being founded in 1999, IPC has been an innovator of thermal packaging solutions. We have spent over a decade studying, perfecting, consistently producing and delivering effective cold chain thermal packaging to companies shipping medicines, foods, and industrial goods worldwide. IPC designs and manufactures, in-house, a variety of custom temperature control products for the cold chain shipping industry.

All of IPC’s solutions provide high performance, while remaining space-efficient and green. We thrive on special requirements including custom sizes, extended shipping durations, unique temperature requirements, and sustainability. Maintaining strict temperatures, maximizing payload, and minimizing weight and preparation time are the cornerstones of IPC cold chain solutions.

Contact us today to discuss your unique temperature assurance packaging requirements