White papers

The temperature-controlled shipment of products, such as biopharmaceuticals and perishable foods, is a growing segment of the supply chain. An uninterrupted storage and shipment process is essential in ensuring the product’s integrity is sustained throughout. Microbial and metabolic deterioration caused by temperature excursions can lead to a significant loss in quality.

The shipping boxes containing temperature-sensitive products should be sturdy, thermally insulated and equipped with sufficient refrigerant to continuously maintain the desired temperature range. Insulating materials are required within the packages to limit the heat transfer between ambient surroundings and the inside of the package, serving to minimize temperature excursions.

Of these insulating materials, Expanded Polystyrene (EPS) coolers are among the most commonly used in the food and pharmaceutical industries. These coolers are considered to be an appropriate solution for the safe and economical transportation of most temperature-sensitive products. EPS coolers are composed of individual cells of low-density polystyrene that impede heat transfer due to their closed-cell structure. However, with a relatively low R- value per unit length, EPS alone cannot meet the more stringent thermal requirements of various industries.

IPC offers a unique and cost-efficient addition to EPS coolers, strengthening their thermal performance while reducing transportation costs for shipment of temperature-sensitive products.

State of the Art Technology

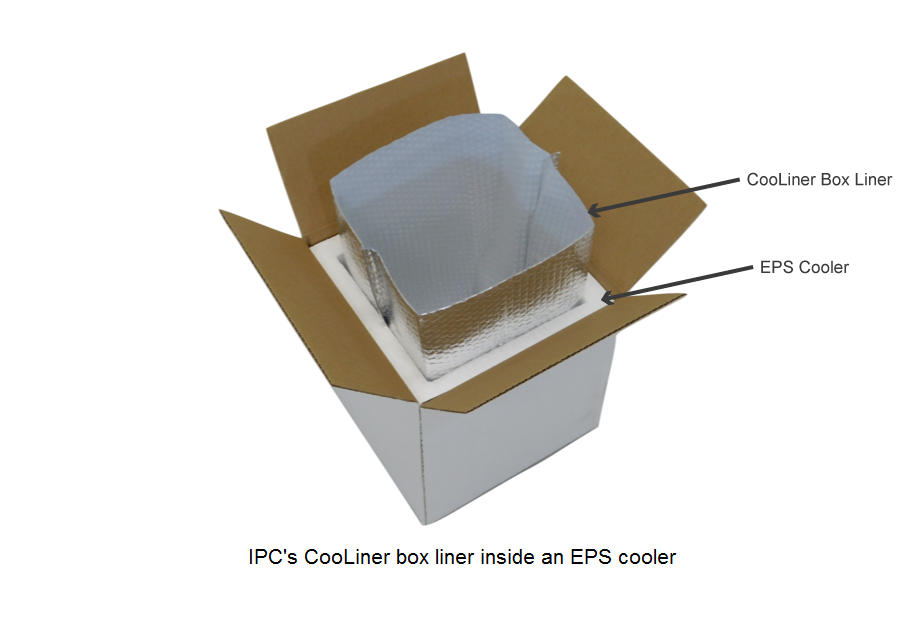

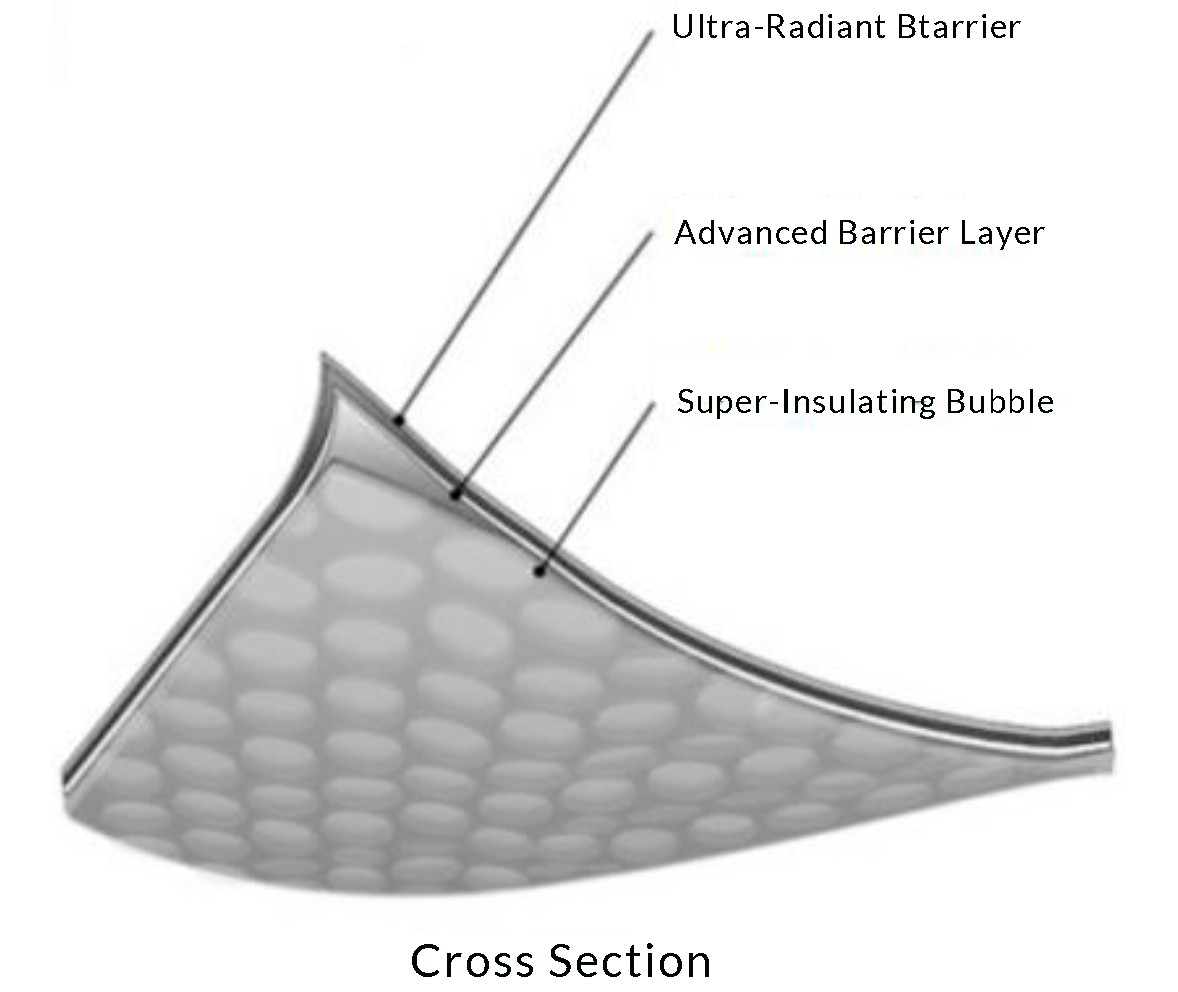

IPC’s CooLiner insulated box liner is a simple, easy-to-use insulation bag, flexibly made to fit shipping containers of any size. The thermal box liner consists of metalized films and air bubbles. The combination of the reflective insulation layer and bubble material prevent both conductive and radiative heat transfer.

The CooLiner insulated box liners are shipped folded, making them space-efficient for warehousing and transport.

IPC’s insulated shipping boxes boast the following features:

- Used with a carton to make an instantly insulated shipping container

- Completely leak-resistant/water-tight

- Raw materials approved by the FDA for incidental food contact

- Extreme space efficiency

- Fully recyclable

- One piece, easy placement in gusseted square-bottom bag design

IPC’s CooLiner Insulated Box Liner inside Styrofoam cooler.

Cross-section of IPC’s CooLiner Insulated Box Liner.

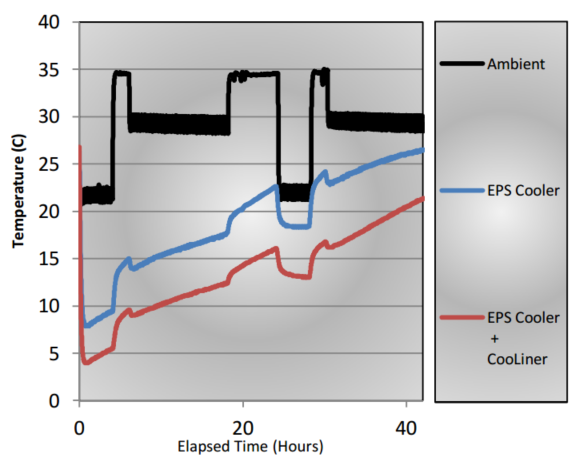

Experiment: Additional Thermal Protection Provided by CooLiner Box Liner

An experiment was devised to evaluate the insulation augmentation that the CooLiner insulated box liners provide.

In the test, IPC’s CooLiner box liner was inserted inside an EPS cooler to be tested under controlled conditions in an industrial oven to assess the added thermal protection. Two bottles of vitamin water and 3 lb of gel-packs were placed in the CooLiner box, and the same was placed inside only the EPS cooler.

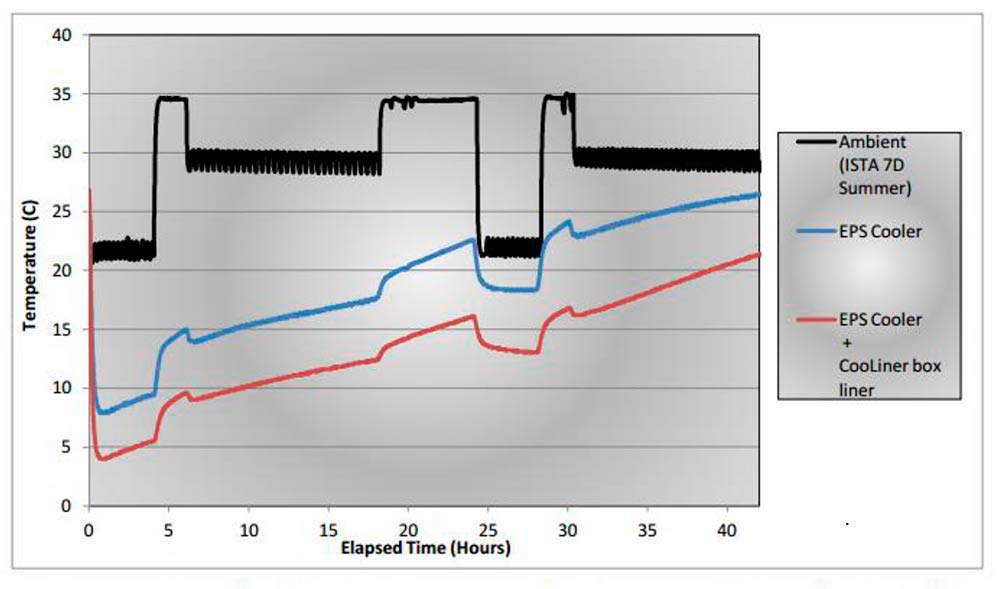

The temperature profiles of the oven and air inside the EPS cooler with and without IPC’s CooLiner box liner is shown below. Despite the fact that the initial air temperatures inside the samples were equal, the addition of the insulated box liner significantly improved the thermal performance of the EPS cooler – confirmed by a 5.1 °C temperature difference inside the thermal container after 42 hours. Other than the added thermal insulation provided by the insulated box liners, the CooLiner forms an extra-closed thermal system, causing the interior temperature to decrease substantially at early stages.

Summary

This direct comparison demonstrates the additional thermal protection provided by the CooLiner insulated box liner in EPS coolers. Although EPS insulated containers are among the most widely used thermal products in the food and pharmaceuticals industries, the mediocre thermal performance fails to meet the thermal requirements of various industries. The CooLiner insulated box liners provide an affordable added layer of thermal protection to EPS coolers, without the downsides of high shipping costs and large storage requirements.

About Insulated Products Corporation (IPC)

Founded in 1999, IPC has been an innovator of thermal packaging solutions. We have spent over a decade studying, perfecting, consistently producing and delivering effective cold chain thermal packaging to companies shipping medicines, foods, and industrial goods worldwide. IPC designs and manufactures, in-house, a variety of custom temperature-control products for the cold chain shipping industry.

All of IPC’s solutions provide high performance, while remaining space-efficient and green. We thrive on special requirements including custom sizes, extended shipping durations, unique temperature requirements, and sustainability. Maintaining strict temperatures, maximizing payloads, minimizing weight and preparation time are the cornerstones of IPC’s cold chain solutions.

Contact us today to discuss your unique temperature assurance packaging requirements.