As e-commerce continues its explosive growth trajectory, further heightened by the COVID-19 pandemic, the pressure on last-mile delivery can be expected to grow. Consider that consumers spent $861.12 billion online with U.S. merchants in 2020. That translates into an increase of 44% in online sales, year over year. It was almost triple the 15.1% uptick in 2019. The term last-mile delivery refers to the final link in the forward supply chain, from a transportation hub to a final destination such as a consumer residence.

Rapidly increasing volume continues to strain existing infrastructure and is exasperated by customer expectations for free delivery and same-day delivery. According to one survey of logistics providers, 57% of their customers demand same-day delivery. No surprise, last-mile delivery has been found to generate 41% of total supply chain costs compared to 13% for warehousing.

In a 2020 report, Last Mile Sprint: State of Mobility in Transportation and Logistics, last-mile delivery was found to be the most inefficient process of the entire supply chain, according to 59% of transportation and logistics companies in the United States and 78% in Canada.

As companies face rapidly increasing ecommerce volume, you can employ some strategies to help contain and reduce last-mile delivery costs. Let’s take a closer look.

1. More efficient vehicles

Given the opportunity to address supply chain costs through more efficient delivery, it is no surprise that a lot of investment has gone into final mile delivery vehicle innovation to specifically address this challenge, including electric-powered vehicles, drones and autonomous solutions. While drones and autonomous vans might be solutions that are a few years away, companies are developing electric vehicles that can offer relief in the short term. For example, Amazon recently launched delivery by EV in Los Angeles, with plans to expand to 15 U.S. cities in 2021. It intends to have 10,000 such delivery vans on the road by 2022 and 100,000 by 2030.

2 Optimizing those final 50 yards

The final 50 years is a crucial component of last-mile delivery. A lack of convenient parking can result in delivery vehicles having to waste time in finding a parking location, as well as the walking distance required to make a final delivery. General Motors also recently announced its BrightDrop EV program, and as part of it, has already successfully tested its EP1, a specialized delivery pallet for that final 50 yards of delivery. During a pilot, FedEx Express couriers effectively and safely handled 25% more packages per day with the EP1s. Companies such as UPS are exploring electric powered bikes as a useful solution for congested urban areas – one that helps resolve the problem of finding a place to stop when parking spots are in short supply.

3 Automated dispatch and routing technologies

If you have drivers waiting for their next route assignment, there is a better way. Automated dispatch technology can automatically make sense of the barrage of new orders and logically organize them into drops for each driver, allowing them to maximize deliveries and minimize travel time. Some delivery services such as Onfleet, for example, provide predictive arrival times and a real-time view of driver locations.

Optimization of routes can be complicated. There are several variables such as distance, time, location, daily traffic patterns, driver hours, EV vehicle travel range, and customer delivery windows to consider. Automated routing software can quickly crunch the numbers and get drivers on the road.

4 Providing multiple delivery options

Fastest isn’t always necessarily best for online purchase delivery. In one survey, 73% of participants said a convenient delivery time is more important to them than a speedy delivery. Having flexible options can translate into fewer costly same-day deliveries and reduce the need for repeat deliveries resulting from customers not being at home.

5 Verifying deliveries and providing customer visibility

Delivery technology, including software and mobility solutions such as smartphones and tablets, allows drivers to capture delivery information immediately. You can quickly determine where packages were dropped, or who signed for them, proving invaluable in assisting customers in finding packages and monitoring delivery performance. Some solutions allow customers to directly message the driver, which can help in finding your anticipated delivery.

Real-time visibility technology also enables customers to have a granular understanding of where their package is in the supply chain and when they should expect its arrival. As a result, customers are more likely to be at home or make arrangements to ensure their package’s safe receipt, thus streamlining the delivery process and reducing the risk of theft.

6 Harnessing real-time data to power continuous improvement

Easily accessible data regarding delivery performance can help drive fresh insights to improve last-mile effectiveness and reduce costs. Software can allow you to analyze information regarding average time per drop, idle time, miles per drop and route, and failed deliveries. Such data can help you pinpoint bottlenecks or other inefficiencies in your last-mile solution. For example, it can help you identify which days or times of day are best for delivery or issues with particular routes. If some drivers are outperforming others, it provides a window into exploring best practices that others can replicate. By analyzing delivery data, you are poised for continuous improvement toward boosting productivity.

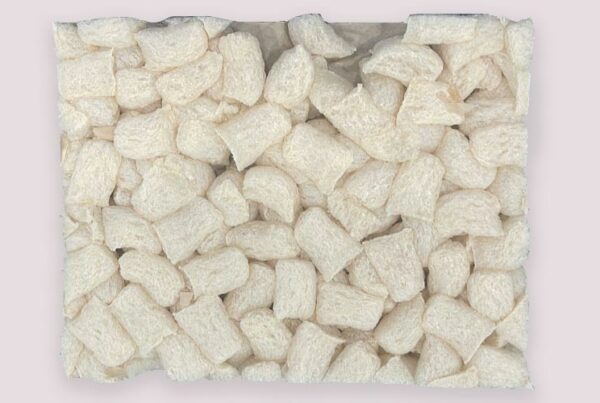

7 Utilizing passive insulated packaging to reduce the need for refrigerated transport

Another great way you can reduce last-mile delivery cost by using passive insulated packaging for chilled or frozen products. Let’s face it: the requirement for reefer or refrigerated delivery trucks can significantly increase your delivery expenses. By choosing the proper insulated packaging as well as a sufficient amount and correct class of refrigerants such as cold packs, you can keep your perishable products within the appropriate temperature range and safe from spoilage – without the need for reefer equipment.

Choose the best option for the product. Options include insulated box liners, insulated bags with corner gussets already made to fit a box, an insulated pouch, or an insulated pallet cover, depending on the quantity and size of goods you are shipping and the duration of the transit. These specialized packaging products are available from IPC and are manufactured using advanced thermal materials that substantially inhibit heat transfer.

The demand for last-mile delivery is growing fast, but the good news is that there are many ripe opportunities for improving performance and cutting costs. Some of those strategies, such as insulated packaging, can be implemented quickly and inexpensively to help improve your bottom line.