A multinational supplier of nutritional supplements seeks to maintain its probiotic products within a 2-8ºC temperature range during storage and transport. It is imperative that the desired temperature range is maintained all the way from manufacturing sites to wholesale retailers and customers.

The storage condition is determined by stability data and any divergence from the proposed temperature range will result in irrevocable and costly damage; a product will lose its potency and market value. Brand integrity, market share, and customer satisfaction are also at risk with unreliable cold-chain transportation of these probiotic goods.

Proposal

The probiotics manufacturer approached IPC with the desire to procure a custom box liner that could be used to maintain the temperature of their probiotic capsules within the acceptable range during transit.

Until now, the manufacturer has been using Expanded Polystyrene (EPS) coolers as their primary insulating solution. However, mounting environmental and performance concerns, especially “last mile” issues, have forced the company to seek an alternative, more sustainable solution.

Custom insulated box liners were required for several sizes of corrugated boxes that the client uses to package and transport temperature-sensitive products from distribution centers to retail stores. The client desired that the insulated box liners should be reusable and earth-friendly to attain a closed-loop lifecycle.

IPC Recommendation: EcoLiner Insulated Box Liner

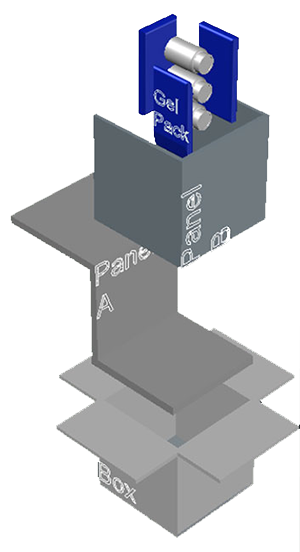

IPC recommended its EcoLiner Insulated Box Liner. The EcoLiner is an insulated shipping container that can be custom-designed to fit the exact dimensions of the client’s corrugated box.

Superior thermal protection. The box liner would provide thermal protection, superior to EPS coolers, by protecting against the inevitable temperature fluctuations experienced during transport and handling. The thermal insulated liners are also resilient enough to be considered reusable, making them ideally suited for the client’s requirements.

Shipped compressed. Another key benefit provided by the EcoLiner is the fact that it is shipped vacuum-compressed. Using patented technology, the EcoLiner’s compact design allows savings of 75% in storage and shipping space when compared to the equivalent size of molded coolers.

Custom samples. IPC provided a custom–sized sample for the company so that the client could thermally and aesthetically assess the product.

Testing and Development

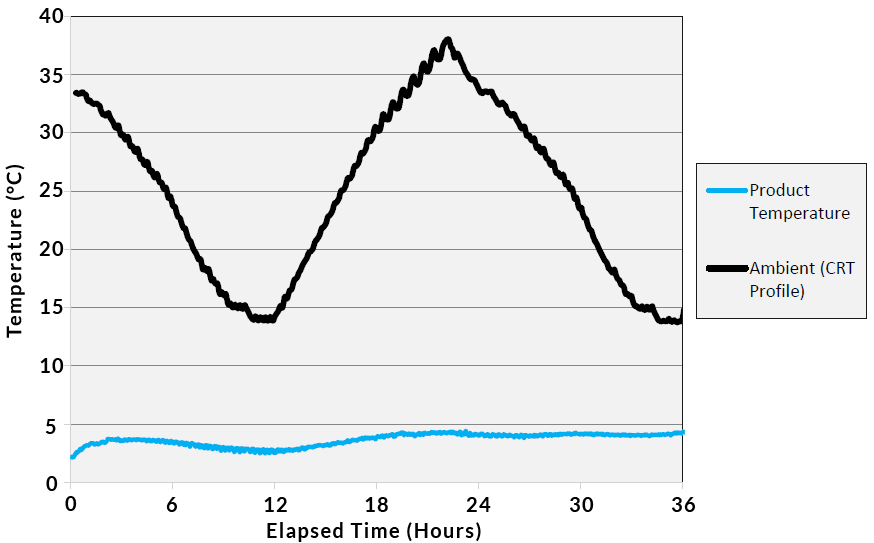

After initial approval by the manufacturer, IPC was provided with the client’s probiotics bottles for testing purposes. At the request of the client, IPC developed a solution that would maintain refrigerated condition for 36 hours under a CRT profile.

The company sought a shipping solution that holds maximum payload while minimizing the box size and use of refrigerants. The preliminary design for operational qualification, which is conducted inside environmental chambers equipped with accurate thermocouples, was based on previous experience and theoretical knowledge of the engineering team. After the pre-qualification phase and loading of all the components, the thermal test was conducted in triplicate.

After preliminary data indicated satisfactory results (shown below), IPC recommended that the company conducts an internal study (performance qualification) to verify that using EcoLiner insulated box liners effectively protect the products during transport via their current routes. The supplement company subsequently conducted multiple trials with several test shipments using EcoLiner box liners.

Conclusion

The probiotics retailer determined that EcoLiner insulated box liners provided adequate protection of the products when exposed to extreme ambient temperatures. This resulted in protection that was more than adequate and ensured that the perishable goods would arrive in an unaffected condition, while satisfying the internal and external regulatory authorities. As of now, the company regularly uses EcoLiner insulated box liners as their primary solution in their closed–loop distribution process.

By using IPC’s EcoLiner insulated box liner instead of EPS coolers, the company has now achieved the following.

- Cradle-to-cradle model by eliminating EPS from its life-cycle.

- Enhanced thermal performance.

- Reduced lead time.

- Large savings in shipping and storage costs stemming from compressibility feature of the EcoLiner thermal box liner.